How to manage the Operations and Maintenance work efficiently in Solar plants

- Sankar

- May 17, 2022

- 5 min read

Updated: Mar 1, 2023

Solar power is one of the fastest-growing industries in the world. Although most developing nations are in the emerging solar market, it has a long way to go and needs to take more adequate steps. Many factors affect solar operations and maintenance, from keeping solar plants running in the most favourable condition, spare management for the smooth plant operation, and international safety protocols (O&M).

It is vital to spot the critical checkpoints in the maintenance of solar power plants, one of the major concerns among different plants for moving towards on-site solar mode. The essential questions that top management of these solar plants fails to answer are: Whom can they rely on for effective maintenance of solar power plants? What is the right way of doing it? How can one ensure the maximum output? There is a need for effective O&M operations in the solar plant, and let us look at a few vital factors that can help manage it properly.

On-site O&M operations

Proper Cleaning: Solar plants consist of so many panels, and thus it is essential to keep removing a layer of dust from these panels. One can even use cold water and a sponge to remove thick dirt or grime and bird droppings. At times, soft detergents are also applied with water for easier cleaning.

Defect Checking: A periodic inspection of the modules is also effective for detecting any possible defects like any unwanted cracks, fogged glazing, chips, or any leakage of water. Regular monitoring helps look out for the damage and keep the module performing appropriately.

Dusting of Inverter/charge controller: To manage it, all you require is performing regular dusting to reduce the dust accumulation. In addition, your technical experts must also ensure that all the indicators, such as LED lights or charge controllers, are functioning effectively.

Wiring and connections: Finally, you must also correctly inspect every wiring done during the installation. Examine any cracks or deterioration (if any) in the insulation. Also, one must adequately review all the connections to check out any corrosion.

Key Challenges

O&M Budget

Cost is always considered the vital aspect of any operations and having said so, it is also an essential part of solar O&M strategy. Since it is also about planning a monthly or yearly expenditure plan, make sure you bring together the interests of all involved stakeholders with the prime ail of controlling costs associated with quality checks or testing procedures for effective maintenance of the system.

Complete documentation

Several operations are performed in a solar plant, so keeping the right track is a big challenge. Therefore, experts always recommend recording all activities at a solar plant. The best gain of having a well-documented record is that it helps stakeholders check and, if needed, remove the loopholes and procedural inconsistencies.

Adequate management of spare parts

Another critical issue generally faced by solar plants is proper storage and management of all essential parts required to operate or install solar panels and other machines. So, it becomes necessary for you to have an inventory management system that can assist you in keeping a proper record of all types of spare parts and quantities. It can be convenient in a sudden breakdown.

Providing the proper training to the workforce

The team consists of different personnel for the operation and maintenance of solar plants. Working under other conditions is never easy and has a different set of challenges for which you must provide the personnel with adequate training. Well-trained personnel are always an asset and help manage tasks effectively and decrease on-site hassles or problems.

However, it is not always easy to keep track of all the operation and maintenance-related activities in a large organization. Many solar plants have opted for various methods to streamline the entire procedure, but nothing proved so effective as using a Computerised Maintenance Management Software (CMMS). The critical aspect of using a powerful tool like Prism CMMS software is that it helps in improving efficiency in two ways. It helps in consolidating different components of maintenance operations into one centralized uniform database. The application can centralize all information for easy access. At the same time, it proves beneficial in the automation of routine tasks, and thus O&M team can save valuable time and resources.

How does Prism software help the O&M Team?

With the help of CMMS software, you gain the ability to have instant access to all essential information about equipment and assets in one cloud-based platform. This includes spare parts available in inventory, purchase of equipment and maintenance history, and critical supporting documentation such as repair manuals and warranties. Prism software is an web and mobile based software that offers you the most important solutions that can help overcome various challenges generally faced in managing operation & maintenance tasks in solar plants:

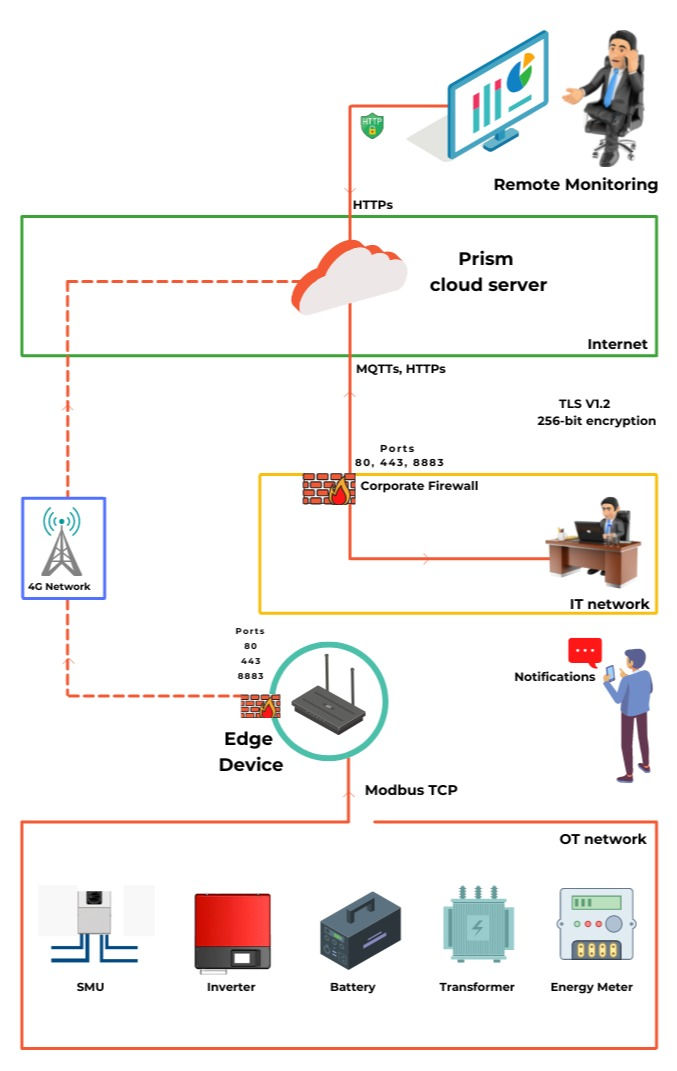

IoT based Asset Maintenance Management Software for Solar Plants

Efficient Solar Plant Maintenance

1. Issuing Maintenance Work Order request

Easy to configure, and the software facilitates you to create the maintenance work order on your mobile. A work order request can be easily created and (usually sent digitally without any need for paper) informs your maintenance staff what needs to be done. The department can easily view all work request details, including work order status, type, dispute area, date, duration, and more. The best aspect is that it allows you to organize and even prioritize work orders for maximum efficiency.

2. Tracking Maintenance Work Order

With the tool's help, it becomes possible to track the work order issued by the operations team until the job is closed out. This particular feature of the software provides an adequate means to keep track of the work order. When you own a trace of the work order, the probability of getting it closed out in time and within the set budget is very high and efficiently possible. Additionally, when you have complete control over the work order tracking, keeping track of all personnel involved also gets simple. All the maintenance work order records are maintained for years together. This will help the O&M team to make informed decisions to optimize the Asset’s Operational Efficiency and Team productivity.

3. Sharing of Maintenance Operational Statistics

The tool also proves beneficial in getting all adequate data or information that can be used for better studying various repair works carried out. This mobile-based platform relay real-time information on all the actions happening on the solar plant directly to the senior management levels. There is complete transparency in the exchange of information between respective departments and the plant’s mid-level to very junior levels. Thus, the entire management structure can get familiar with and know the issues maintenance workers face.

4. Intelligent Reports for efficient planning

Any solar plant or firm's day-to-day functioning gets smooth if there is the right platform that helps generate reports on the entire work of the departments. The software provides you with a good CMMS system where one can create reports without any requirement of active interference from the people handling the maintenance. The annual or monthly report can give you an accurate view of the health of the solar plant or machinery.

The future of maintenance seems to move towards automated ways, and CMMS software is playing a significant role. The solution helps you track equipment use, draft asset profiles, make cost-saving business decisions and eventually attain your maintenance goals.

5. Connected Assets for Operational Efficiency

Prism IoT gateway connects the inverters, batteries, and other sensors in the solar plant, and collects real-time data from them.

Prism software helps the O&M team visualize the data on a web based SCADA screen, and create custom reports on the historical data.

Prism monitors the condition of the equipments continuously, alerts the Maintenance team to create a Preventive Maintenance work orders depends on the equipments internal status and fault scenarios.

AI based predictive analysis on the plant data suggests the O&M for Predictive Maintenance work before the failure of the equipments occurs.

List of critical parameters to monitor in a Solar Plant

Solar Panel | Inverter | Battery | Transformer |

|---|---|---|---|

DC Voltage | DC Input Voltage | State of Charge (SoC) | Oil Temperature |

DC Current | DC Input Current | Voltage | Winding temperature |

DC Power | AC Output Voltage | Current | Voltage |

Temperature | AC Output Current | Power | Current |

| AC Output Frequency | Temperature | Oil level |

| Efficiency | Capacity | |

| | Impedance | |

| | Self Discharge | |

Other Plant level Parameters

Wind Speed |

Irradiance |

Grid Status |

Errors and Alarms |

Live & Historical Reports

Energy Generation Report |

Overall Plant Performance Report |

Power Output Report |

Irradiation Trend Analysis Report |

Weather Report |

Inverter Efficiency Report |

Battery Performance Report |

Transformer Status Report |

Grid Connection Report |

Alarm and Event Report |

Overall Plant Maintenance Summary Report |

Hourly, Daily, Weekly, Monthly Power Production Summary Report |

Comments