Empowering Maintenance Teams to achieve ISO Certifications and pass Audits with Prism Software

- Sankar

- Dec 1, 2024

- 4 min read

Updated: Dec 5, 2024

Achieving certifications and passing audits are not just regulatory requirements but essential milestones that showcase an Organization’s commitment towards quality, safety, and sustainability. Maintenance teams play a pivotal role in ensuring compliance with stringent standards like ISO 9001, ISO 14001, ISO50001, ISO 55001, etc. However, meeting these requirements can be challenging without the right tools. This is where an IoT-based cloud-based Prism Enterprise Asset Management Software play a crucial role.

Our Prism Software is designed to support maintenance teams in managing their operations while ensuring compliance with certification standards and audit requirements. By leveraging features like maintenance management, asset and spare parts inventory, energy monitoring, and environmental tracking, our software simplifies the path to certification and audit readiness. This blog delves into how our solution helps maintenance teams excel in these areas.

1. Simplifying Maintenance Management

Effective Maintenance Management is the cornerstone of a well-functioning factory. Our Prism Software streamlines every aspect of maintenance, from scheduling preventive tasks to tracking repairs.

Automated Preventive Maintenance:

Certification bodies like ISO 9001 emphasize the importance of consistent and well-documented maintenance practices. Our software automates the scheduling and tracking of preventive maintenance, ensuring that no task is overlooked. This reduces the risk of equipment failure and supports continuous operational excellence.

Centralized Documentation:

Maintenance logs, repair histories, and compliance records are securely stored and easily accessible. This audit-ready documentation minimizes the time and effort required during inspections.

Performance Metrics:

Metrics like Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) are tracked automatically, providing measurable insights into equipment performance. These metrics not only help achieve certifications like ISO 9001 but also improve overall productivity.

Certifications Supported:

ISO 9001 (Quality Management), ISO 55001 (Asset Management)

2. Efficient Asset Inventory Management

Keeping track of assets is critical for maintenance teams aiming to achieve certifications such as ISO 55001. Our software offers robust tools for managing assets throughout their lifecycle.

Comprehensive Asset Tracking:

With IoT-enabled features, you can monitor all assets in real-time. This includes maintenance history, warranties, and lifecycle stages, ensuring that every asset complies with certification requirements.

QR Code Integration:

Maintenance teams can access asset details instantly by scanning QR codes. This feature is particularly useful during audits, where quick and accurate information retrieval is essential.

Predictive Maintenance:

By leveraging IoT data, the software predicts potential failures and alerts the maintenance team, reducing downtime and ensuring compliance with asset management standards.

ISO Certifications Supported:

ISO 55001 (Asset Management)

3. Streamlined Spare Parts Inventory Management

A well-organized spare parts inventory ensures that maintenance tasks are completed on time, supporting operational efficiency and compliance.

Real-Time Tracking:

Our software tracks spare parts inventory in real-time, ensuring that critical components are always available. This reduces downtime and supports preventive maintenance schedules.

Cost Optimization:

The system provides insights into inventory usage patterns, enabling cost-effective management without overstocking or understocking.

Audit-Ready Reporting:

Detailed records of spare parts usage are maintained, simplifying the process of demonstrating compliance during audits.

ISO Certifications Supported:

ISO 9001 (Quality Management)

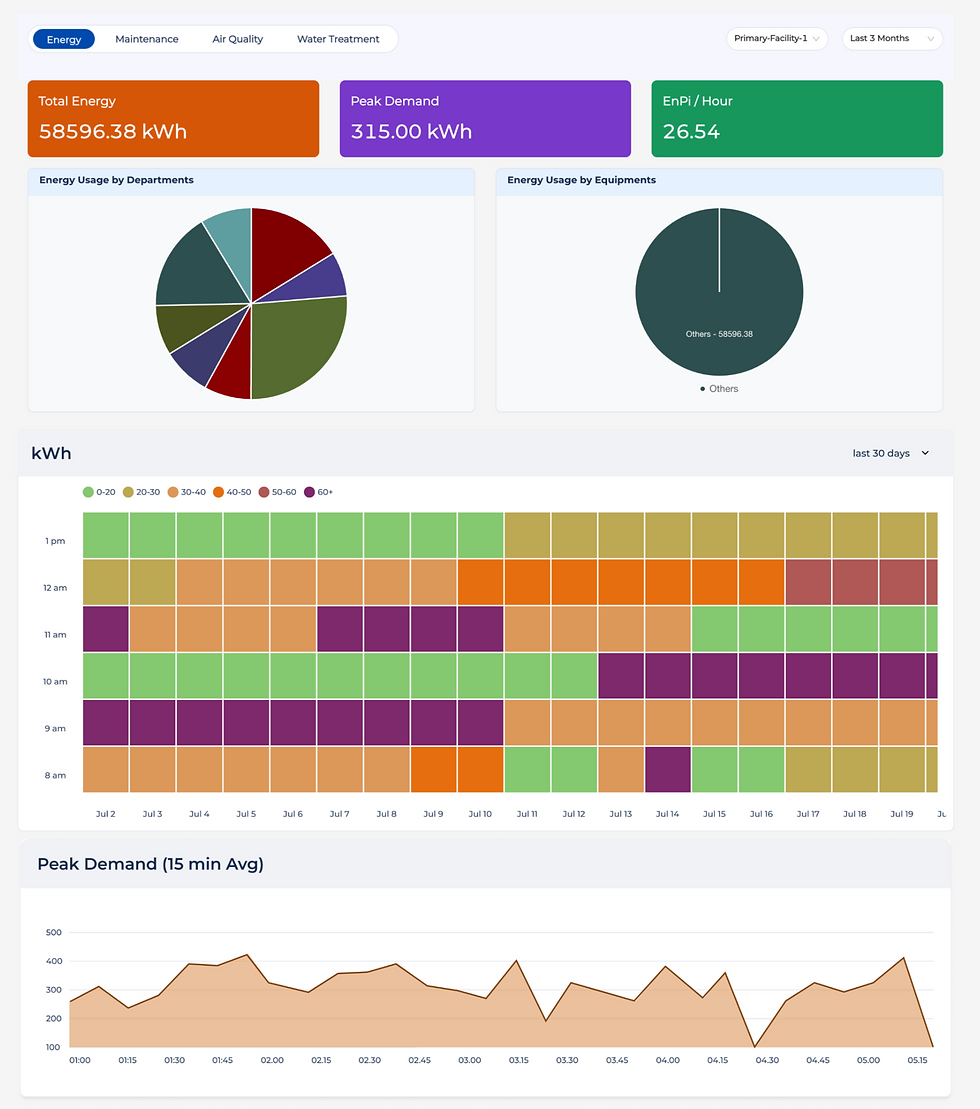

4. Advanced Energy Monitoring

Energy management is an integral part of modern factories, with certifications like ISO 50001 focusing on improving energy performance. Our software provides real-time insights into energy consumption.

Energy Consumption Analysis:

Track energy usage across different equipment and identify areas of inefficiency. This helps in reducing energy costs and aligning with sustainability goals.

Benchmarking and Reporting:

The software generates energy reports that highlight key performance indicators, making it easy to demonstrate compliance during energy audits.

Sustainability Practices:

By identifying and eliminating energy wastage, our software supports a factory’s efforts to meet environmental standards like ISO 14001.

ISO Certifications Supported:

ISO 50001 (Energy Management), ISO 14001 (Environmental Management)

5. ETP and STP Monitoring

Compliance with environmental regulations is crucial for certifications like ISO 14001. Our software simplifies the monitoring of Effluent Treatment Plants (ETP) and Sewage Treatment Plants (STP).

Real-Time Monitoring:

Prism IoT Edge Gateway collects real-tim data from IoT sensors deployed at ETPs and STPs and lets the user monitor the key parameter from PC/Laptop/Mobile remotely and ensures that they operate within regulatory limits. Alerts are sent by email/sms when deviations occur, enabling prompt corrective actions.

Compliance Reporting:

The system generates detailed reports of effluent and sewage parameters, which can be presented during environmental audits.

Proactive Alerts:

Real-time notifications ensure that any potential compliance issue is addressed before it becomes a problem.

ISO Certifications Supported:

ISO 14001 (Environmental Management)

6. Utility Monitoring for Efficiency

Utilities like water, air, gas, and electricity are essential for factory operations. Monitoring their usage is critical for achieving energy and environmental certifications.

IoT-Enabled Tracking:

Our software tracks utility usage in real-time, providing actionable insights into consumption patterns.

Optimization Opportunities:

By identifying inefficiencies, the software helps the maintenance team implement corrective measures to reduce costs and resource usage.

Audit Trail:

Detailed utility usage data is stored in the system, making it easy to demonstrate compliance during audits.

ISO Certifications Supported:

ISO 14001 (Environmental Management), ISO 50001 (Energy Management)

Key Features supporting Certifications and Audits

Centralized Data Management:

All data, from maintenance logs to environmental parameters, is stored in a centralized location, accessible through intuitive dashboards.

Customizable Reports:

Generate tailored reports to meet specific audit requirements, saving time and effort during inspections.

Real-Time Notifications:

The software alerts maintenance teams to overdue tasks, compliance gaps, and upcoming audits, ensuring proactive management.

Traceability and Audit Trails:

Every action in the system is logged, creating a complete traceability record required for certifications and audits.

Transforming Audits from Burden to Opportunity

Traditionally, audits and certifications have been seen as burdensome tasks requiring significant time and effort. With our IoT-based CMMS software, they become opportunities for continuous improvement. By automating compliance tracking, providing actionable insights, and generating audit-ready reports, the software not only simplifies the certification process but also drives operational excellence.

Conclusion

In a world where regulatory compliance and operational efficiency go hand in hand, Prism Software empowers maintenance teams to excel. By integrating features like maintenance management, asset and spare parts inventory, energy monitoring, and environmental tracking, the software simplifies the journey to achieving certifications and passing audits.

With our IoT based Prism Software, maintenance teams can focus less on paperwork and more on what truly matters—keeping the factory running smoothly, efficiently, and sustainably. Whether it's ISO 9001 for quality, ISO 14001 for environmental management, ISO 50001 for energy efficiency or ISO 55001 for asset management Prism is your trusted partner in compliance and excellence.

Comments